Enthusiast Corner

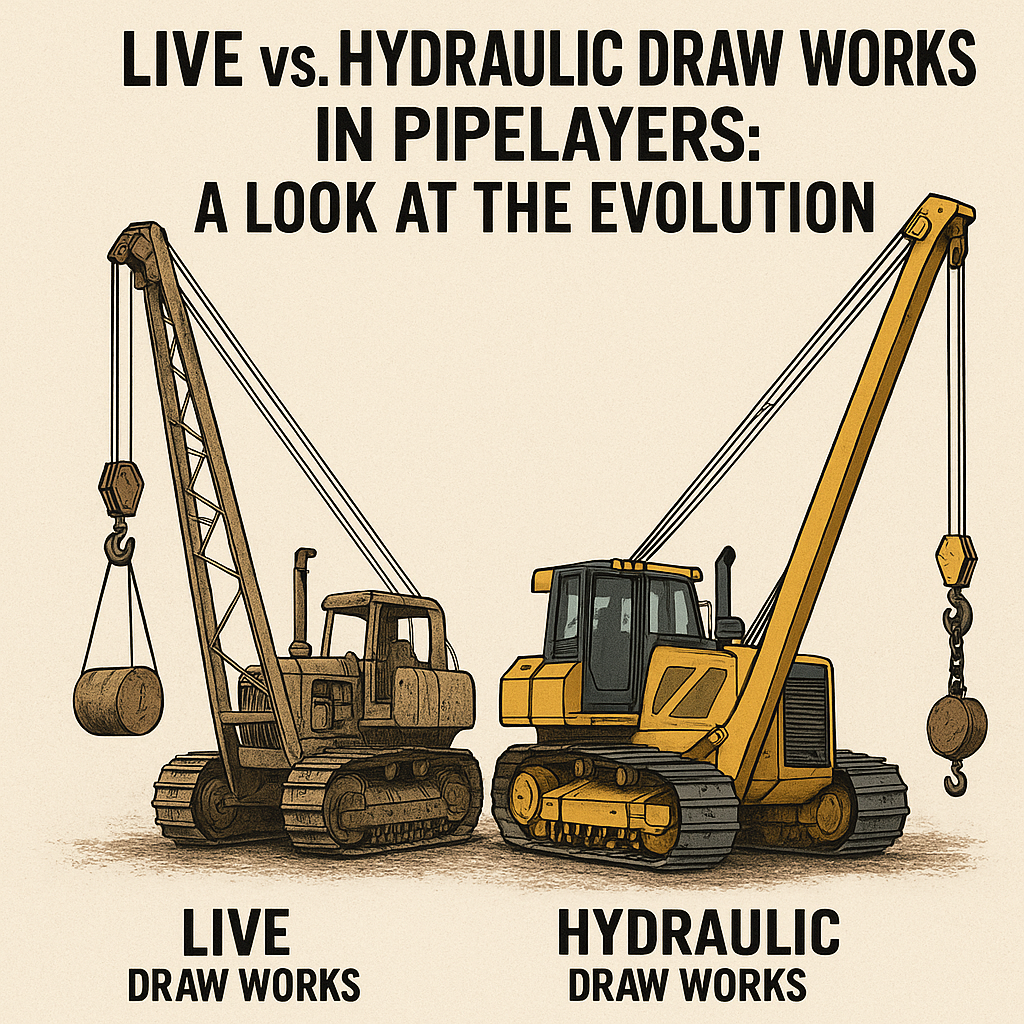

Live vs. Hydraulic Draw Works in Pipelayers: A Look at the Evolution

In the world of pipelayers, where safety, precision, and reliability are non-negotiable, the technology behind draw works has quietly gone through a major transformation. At the heart of that evolution? The shift from live draw works to hydraulic systems.

This change didn’t happen overnight—but it has made a serious impact on how modern pipelayers operate. Whether you're a seasoned operator or just getting familiar with pipeline equipment, understanding the differences between these two systems gives real insight into how the industry has progressed.

What Is Live Draw Works?

The live draw works system is a mechanical setup powered directly off the engine through a series of gears and clutches. It's called "live" because the drum is always engaged when the engine is running, meaning it's always moving unless actively disengaged.

This setup was standard on older pipelayers, especially those built in the mid-to-late 20th century. Brands like Caterpillar used this design extensively in models like the D7 and D8 series.

Advantages of Live Draw Works:

• Simple, mechanical design with fewer electronic components.

• Direct, responsive power transfer.

• Easily serviced with basic tools and mechanical know-how.

Limitations:

• No load-holding capability without additional brake systems.

• Less precise control during delicate lifting or lowering.

• Requires more skill and attentiveness from the operator to avoid over-spooling or free-falling loads.

The Rise of Hydraulic Draw Works

As technology advanced, hydraulic draw works began replacing mechanical systems. In a hydraulic setup, the winch is driven by a hydraulic motor, giving operators much finer control over lift and line speed.

Modern pipelayers from brands like Liebherr, Volvo, and newer Cat models often feature fully hydraulic draw works as standard.

Advantages of Hydraulic Draw Works:

• Precise, smooth control—especially useful in critical lift situations.

• Built-in load-holding valves enhance safety.

• Easier integration with modern machine electronics and controls.

• Reduced wear and tear due to controlled movement.

Limitations:

• More complex systems with pumps, hoses, and valves—can be more costly to repair.

• Dependent on hydraulic system health—contaminated fluid or leaks can affect performance.

The Progression: From Grit to Precision

The move from live to hydraulic draw works reflects a broader trend in heavy equipment: increasing focus on safety, precision, and operator comfort.

In the early days, a skilled operator could work miracles with a live draw works system, but it came at the cost of constant attention, physical strain, and higher risk. Hydraulic systems have opened the door for more consistent performance, less operator fatigue, and safer operations—especially on modern job sites where regulations are tighter and tolerances are lower.

While some old-school operators still swear by the responsiveness of a live draw works system, there's no denying the advantages of hydraulic technology in today’s pipelaying world.

If you're running a mixed fleet or considering upgrades, it’s important to understand not just what’s under the hood, but how that technology impacts your crew, productivity, and bottom line.

Whether you prefer the raw simplicity of mechanical systems or the finesse of hydraulics, one thing is clear: pipelaying has come a long way—and the draw works system is a big part of that story.