Iron Insights

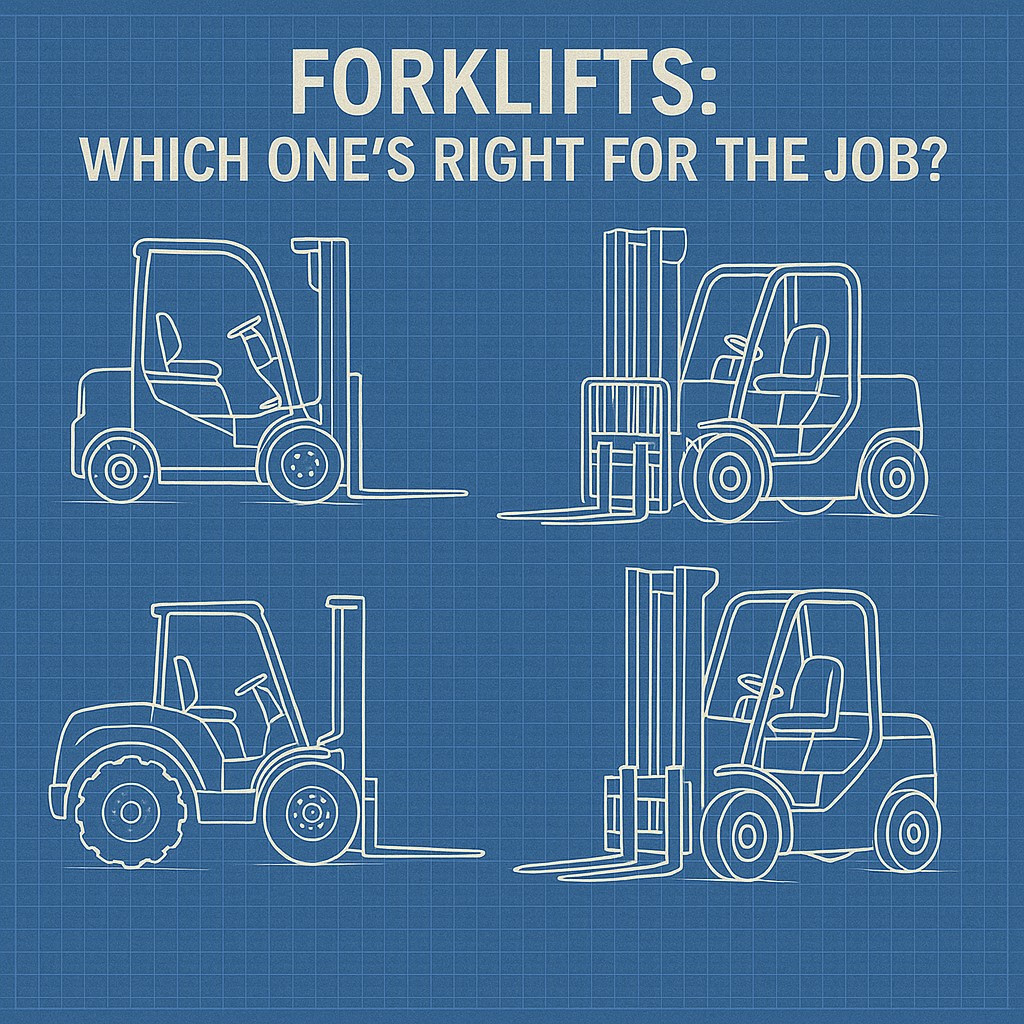

Choosing the Right Forklift: A Comparison Guide

In the world of heavy equipment, not all forklifts are built the same. Whether you're lifting pallets in a warehouse, unloading pipe on a construction site, the right forklift can make or break productivity — and safety.

Here’s a breakdown of the most common types of heavy equipment forklifts and where each one shines.

Telehandlers (Telescopic Handlers)

Best for: Construction sites, agriculture, rough terrain

Key Features:

• Extendable boom gives reach and height beyond standard forklifts

• Can be fitted with different attachments (buckets, winches, lifting hooks)

• Handles heavy loads and uneven surfaces with ease

Why it stands out:

Telehandlers are like the Swiss Army knife of forklifts. If you need both reach and power — and you're working off-road — this is your machine.

Rough Terrain Forklifts

Best for: Outdoor material handling on uneven ground

Key Features:

• Large pneumatic tires for traction on dirt, gravel, and mud

• Higher ground clearance

• Typically powered by diesel for torque and strength

Why it stands out:

Purpose-built for job sites, lumber yards, and farms. If the ground’s not smooth, a rough terrain forklift keeps things moving.

Industrial Forklifts (Warehouse Forklifts)

Best for: Warehouses, factories, smooth pavement

Key Features:

• Compact and maneuverable

• Great for stacking pallets and navigating narrow aisles

• Lower lift capacity than telehandlers or RT forklifts

Why it stands out:

Efficient and dependable indoors. Perfect for loading docks, racking, and daily logistics operations.

Heavy-Duty Forklifts

Best for: Ports, steel yards, heavy manufacturing

Key Features:

• Massive lifting capacities (30,000 lbs and up)

• Reinforced frames and counterweights

• Often used with oversized or awkward loads

Why it stands out:

When weight is the priority, these machines do the heavy lifting — literally. Think shipping containers, steel coils, and giant precast elements.

Truck-Mounted Forklifts (Piggyback Forklifts)

Best for: Delivery and material drop-off at job sites

Key Features:

• Mounts to the back of a flatbed or trailer

• Quick to deploy on-site

• Lighter and more compact than other types

Why it stands out:

Perfect for contractors and suppliers who need to unload materials on the go — no waiting for site equipment.

What to Consider When Choosing a Forklift:

• Terrain: Indoors or outdoors? Smooth or rough ground?

• Load Capacity: How heavy and bulky are your materials?

• Reach: Do you need vertical lift or long reach?

• Attachments: Will you need forks only, or other tools?

• Maneuverability: How tight is the space you’ll be working in?

Forklifts may all lift, but they don’t all do it the same way. Choosing the right type can mean faster work, fewer breakdowns, and safer job sites.

Whether you’re hauling timber, moving pipe, or unloading on the fly, there’s a heavy equipment forklift designed for the task — and the right one makes all the difference.

Want help listing or buying the right forklift for your operation? Check out listings on HeavyEquipment.com — or connect with a dealer who specializes in your industry.